RELIAswitch® - the TECHNOLOGY of dependability

When your application can’t afford failure, you rely on Reliaswitch®

For 30 years, Reliatrace® has produced the most reliable custom membrane switches in the industry, powered by our proprietary Double-Sided Polymer Circuitry (D/SPC®) technology. Trusted by leading companies in agricultural machinery, healthcare and commercial beverage, Reliaswitch is the technology you’ll find inside the country’s most dependable electronic assemblies. From farming vehicles to construction machinery to life-saving medical devices, Reliaswitch provides the exceptional durability engineers need for harsh environments and high-performance applications.

Why Reliaswitch? The Double-Sided Advantage

The vast majority of membrane switches currently produced are single-sided, constructed with inherent points of weakness that invite unnecessary risk into your application. Cross-over, bridged or jumper connections are flaws that can commonly cause electrical failure, jeopardizing your entire assembly.

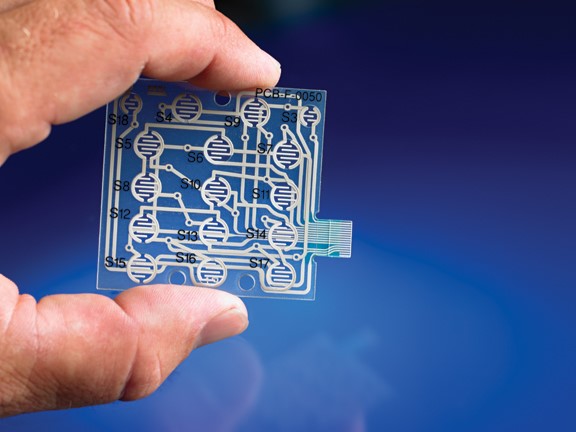

Reliaswitch membrane switches are uniquely constructed to eliminate these points of weakness, employing a specialized screen printing process that enables Reliaswitch circuitry to be printed on both the top and bottom of the circuit substrate, joined by vias. This proprietary technology eliminates the inherent failure points of single-sided membrane switches, greatly reducing the risk of cracks, fractures and open traces.

By design, Reliaswitch doesn’t require a screen printed dielectric to separate traces, as silver is incapable of migrating through the polyester substrate, making the Reliaswitch circuit inherently more reliable.

Curious about other leading causes of membrane switch failure that Reliaswitch reduces or eliminates? Read our full article, “Causes of Membrane Switch Failure”.

PERFORMANCE ADVANTAGES

Exceptional reliability and longevity. Reliaswitch circuitry has a proven history of exceptionally low defect and return rates, in addition to passing stringent tests for longevity and stability.

Reduced risk of cracks, fractures and open traces. These points of weakness are inherently eliminated with the use of our D/SPC technology.

Greatly reduced risk of tail fracture. One of the most common causes of membrane switch failure occurs when the tail is bent or creased near the exit point, resulting in fracture. Reliatrace’s proprietary D/SPC technology allows us to run tail traces from the bottom of the circuit, which enables tail traces to be in compression rather than expansion. This capability eliminates this common cause of circuitry failure.

Durability in harsh environments. Reliaswitch is designed to withstand tough temperature, chemical and mechanical stress.

Sealable, water-resistant designs. Resistance to water and chemical ingress is maximized with more room for gasketing options and the ability to incorporate a full-perimeter seal.

Flexible design with less risk. Printed on polymer thick film, Reliaswitch has the capability to conform to convex / concave surfaces (e.g., handle grips, pipes, and contoured body features) without putting traces in expansion, therefore reducing potential circuitry failures.

Denser packaging. With a smaller circuitry footprint, Reliaswitch allows for higher density of keypad positions and more room for surface-mount technology (SMT) components, especially LEDs and resistors.

Lower stack-up height. In certain designs, we can reduce stack-up height by as much as 7-10 mils.

Tight tolerances. Reliaswitch can be printed with traces as small as 8 mils with a 12 mil space, enabling engineers to eliminate expensive copper circuitry from many high-performance applications.

Redundancy for life-saving devices. Engineers can easily and cost-effectively duplicate critical circuit traces for use in fail-safe applications.

3-axes connections. Enabling innovative designs that aren’t feasible in single-sided membrane switches, Reliaswitch provides the ability to create electrical connections in the x, y and z dimensions.

RoHS compliant. Built using an additive process, our digital and screen-printed membrane switches can be manufactured in compliance, without any banned substances.

COST EFFECTIVE

Focused prototyping. Reliatrace’s 30 years of industry experience enables our clients to reduce multiple trial and error prototype runs, resulting in reduced research, design and development costs.

Lower material cost. Copper circuitry, which is etched in chemical baths, produces a significant waste stream, while Reliaswitch is built using an additive process, producing far less material waste.

Fewer line rejects and field failures. The long-term cost of poorly-constructed membrane switches, which can cause not only circuitry failure, but entire assembly failure, is significant. With circuitry defect rates close to zero, Reliaswitch reduces financial losses due to faulty membrane switches.

How does Reliaswitch® work?

For a detailed explanation of the Double-Sided Polymer Circuitry (D/SPC®) technology used in Reliaswitch®, please visit our Proprietary Technology page.